|

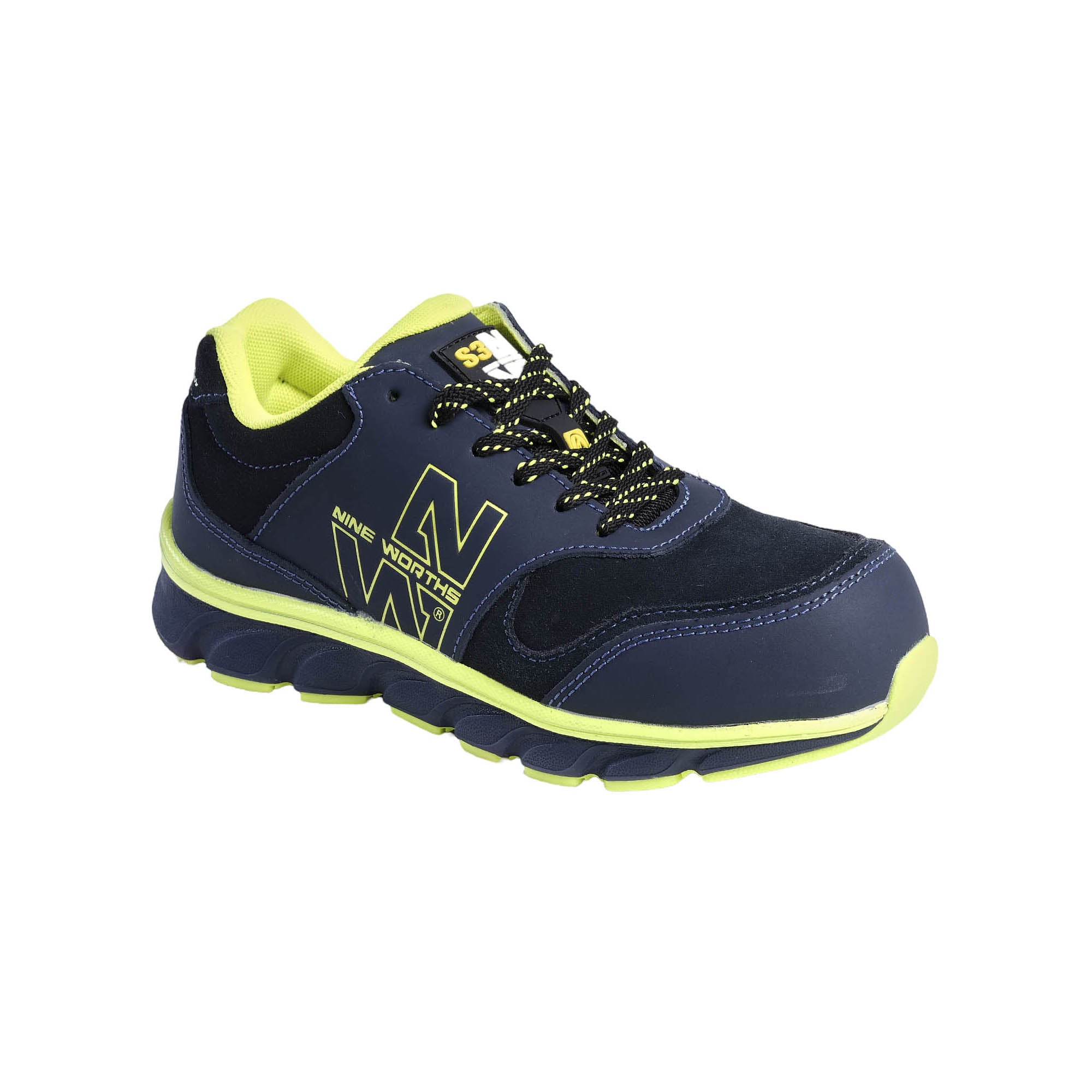

On a construction site, safety shoes are subjected to extreme stresses every day. Abrasive dust, wet floors, repeated impacts, and heavy loads put the materials to the test. An unsuitable pair quickly loses its effectiveness, exposing the worker to risks and leading to premature replacement. The choice of material therefore determines resistance, comfort, and longevity. To properly select men's or women's low-cut safety shoes , it is essential to understand the differences between leather, technical textiles, rubber, and composite materials. Leather, a durable and versatile allyLeather remains a benchmark in the world of work footwear . Its density effectively protects against friction, cuts, and splashes. On a construction site, a high-top leather safety shoe offers solid support and good resistance to mechanical impacts. Full-grain leather, being denser, retains its qualities after many months of use, provided it is regularly cared for. However, leather shows its limitations in very humid environments. Prolonged exposure to water eventually softens it and reduces its durability. To overcome this drawback, some manufacturers combine leather with a waterproofing treatment, creating models adapted to inclement weather. Comfortable safety shoes made of waterproofed leather are therefore suitable for outdoor work in rain and mud. Technical textiles: lightweight and targeted resistanceModern textiles, such as nylon or high-density woven fibers, have become the standard in low-cut safety shoes designed for dry environments. Their lightness improves comfort during long workdays. These breathable materials also prevent the accumulation of internal moisture, a common problem in hot weather. A women's low-cut safety shoe made of technical textile retains its shape longer thanks to the strength of the synthetic fibers. The risk of cracking or splitting is lower compared to poorly maintained leather. However, this type of material is less suitable for highly abrasive construction sites, where contact with concrete or metal demands greater durability. Textiles are therefore better suited to indoor environments, where lightness is more important than absolute strength. |

Rubber and polyurethane soles: the key to gripThe sole is the part of the shoe most exposed to wear. Uneven surfaces, covered in rubble or dust, accelerate its deterioration. Natural rubber is distinguished by its grip, even on wet or greasy surfaces. Men's high-top safety shoes with rubber soles provide superior stability when moving on scaffolding or muddy terrain. Lightweight polyurethane maintains good resistance to hydrocarbons and chemicals. Comfortable safety shoes with polyurethane soles absorb shocks better and reduce muscle fatigue. Tradespeople working on concrete or metal surfaces thus benefit from improved comfort over extended periods. The rubber-polyurethane combination offers both robustness and flexibility, making it the preferred choice for many recent models. Protective shells: steel, aluminum or compositeThe toecap remains the central element of any safety shoe . Steel, used for decades, offers maximum resistance against impacts and crushing. A high-top safety shoe equipped with a steel toecap is more resistant to heavy impacts, but its weight can tire the wearer. Aluminum offers equivalent protection with reduced weight, making the shoe more comfortable to wear. Composite materials, such as fiberglass or carbon fiber, are gaining popularity. They combine lightness, thermal insulation, and non-conductivity. For an electrician or tradesperson working in a sensitive environment, a high-top women's safety shoe with a composite toecap is an ideal option. The durability of safety footwear depends directly on the material chosen. Leather retains its reputation for robustness, especially for high-top models exposed to mechanical impacts. Technical textiles are appealing due to their lightness and comfort, provided they are used in less abrasive environments. Rubber or polyurethane soles determine grip and shock absorption, two essential criteria on a construction site. Finally, the choice of toecap—steel, aluminum, or composite—influences the balance between safety, weight, and insulation. A tradesperson working outdoors in the rain will favor high-top safety shoes made of waterproof leather , while one working indoors will opt for low-cut safety shoes made of technical textiles . Whether for men or women, the careful selection of materials guarantees not only safety but also lasting comfort in the demanding conditions of the worksite. |

|